*10LB and 2.5LB Plates are backordered and will start shipping late February*

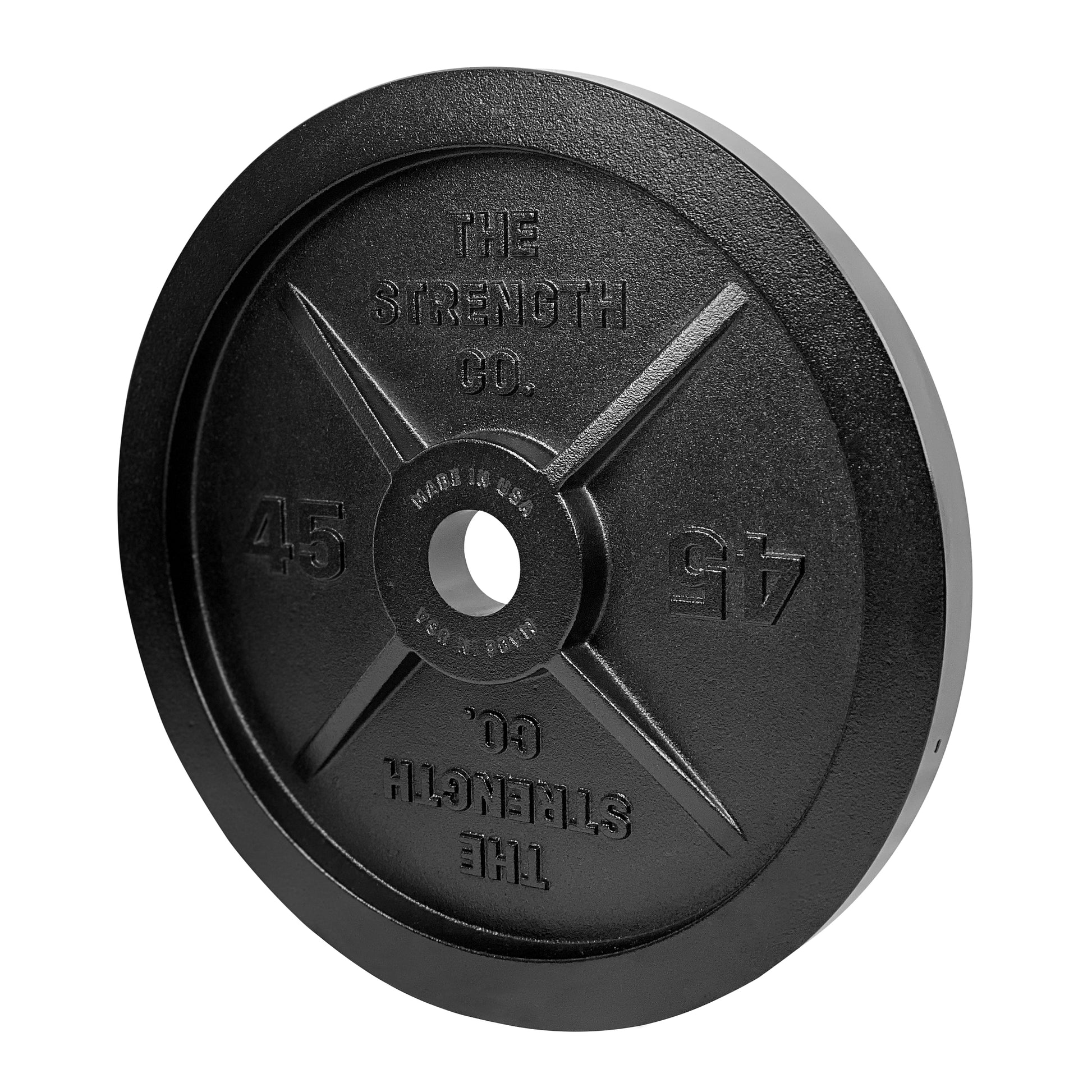

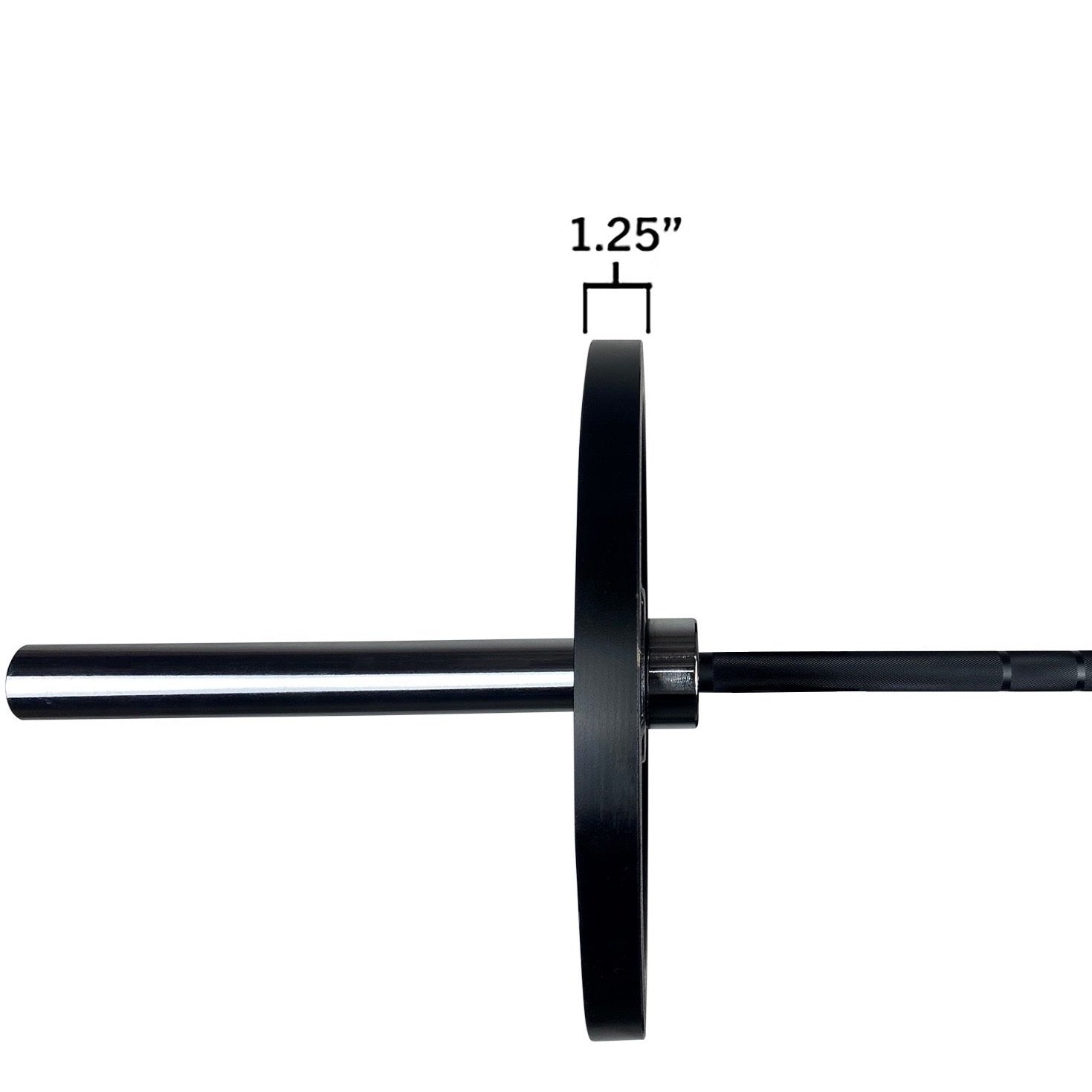

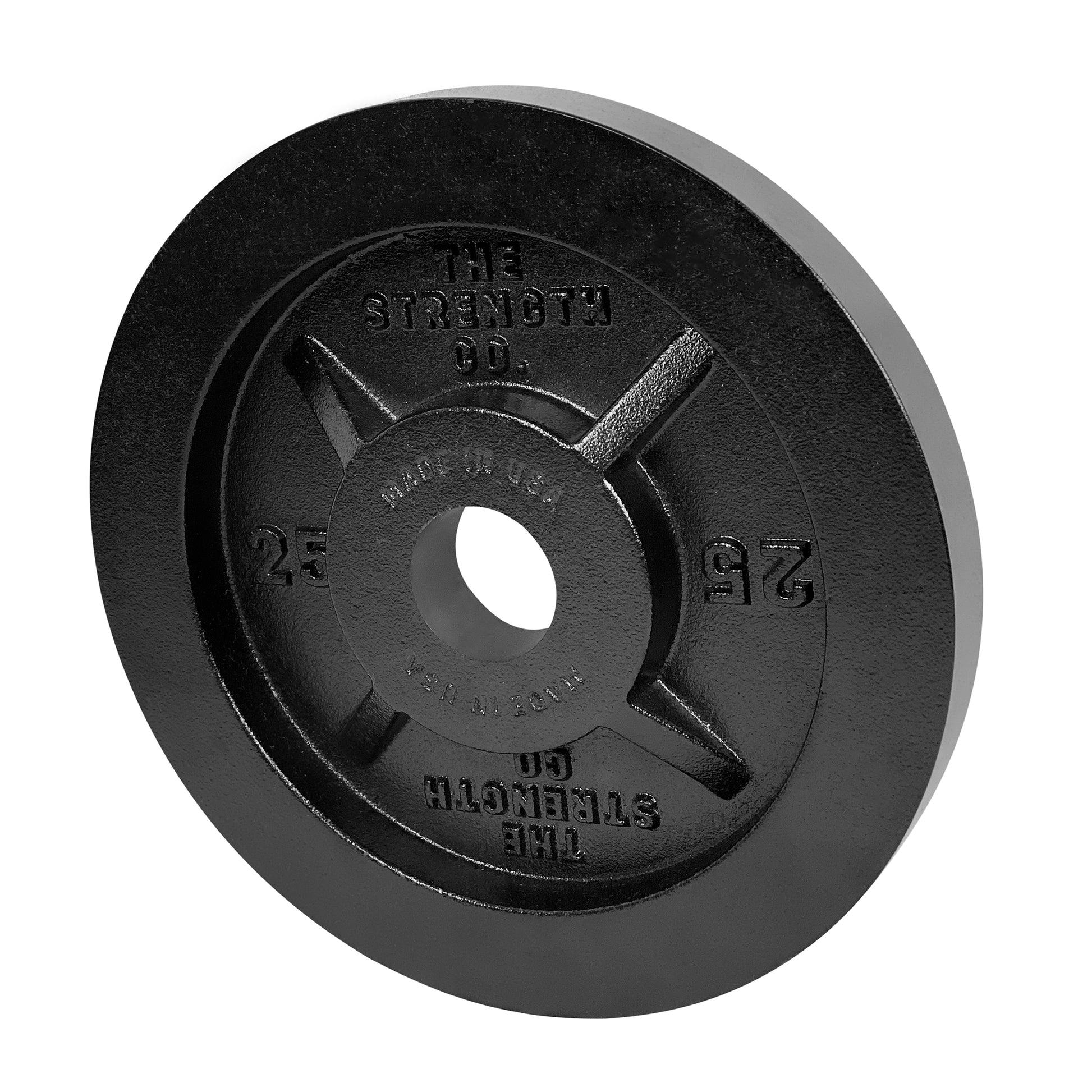

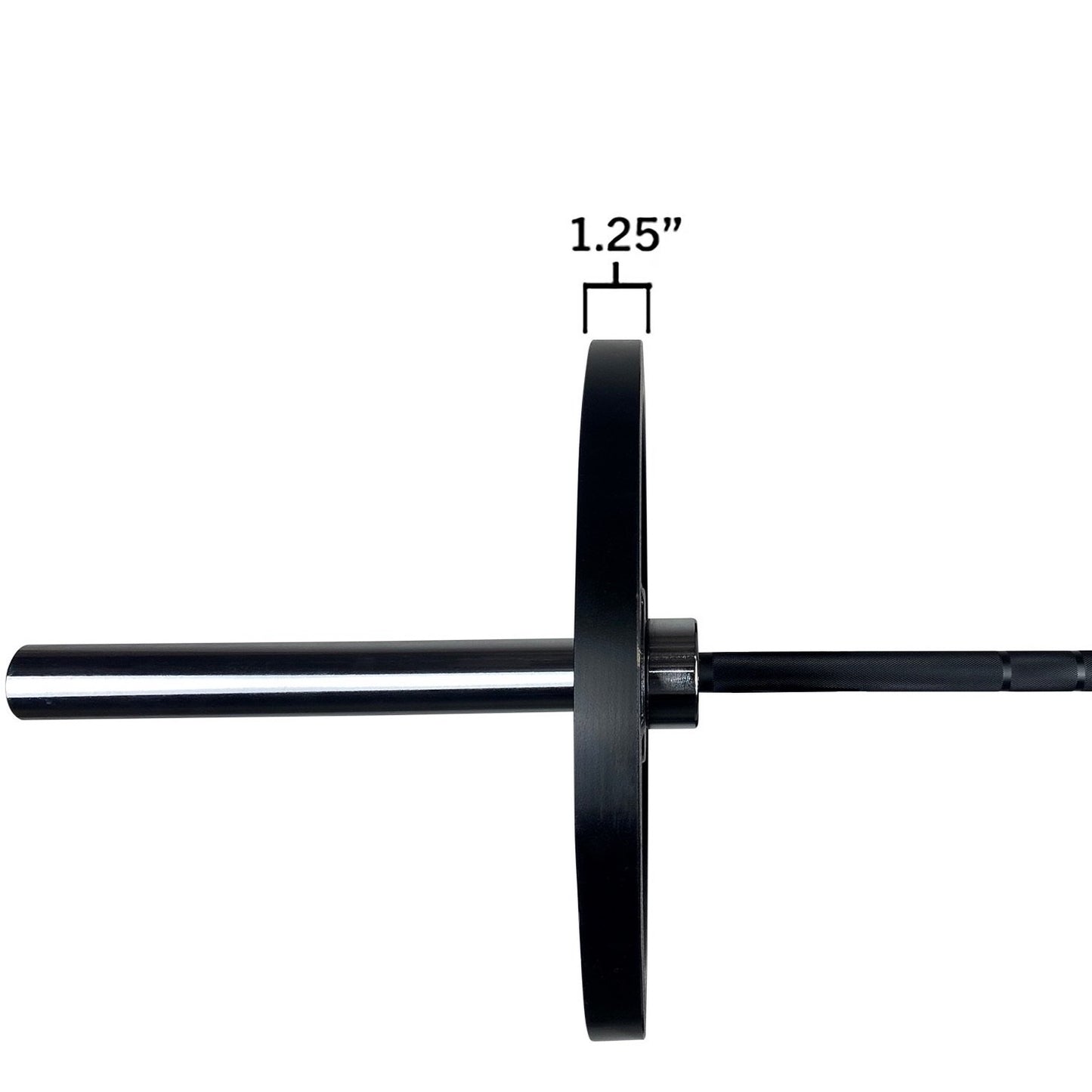

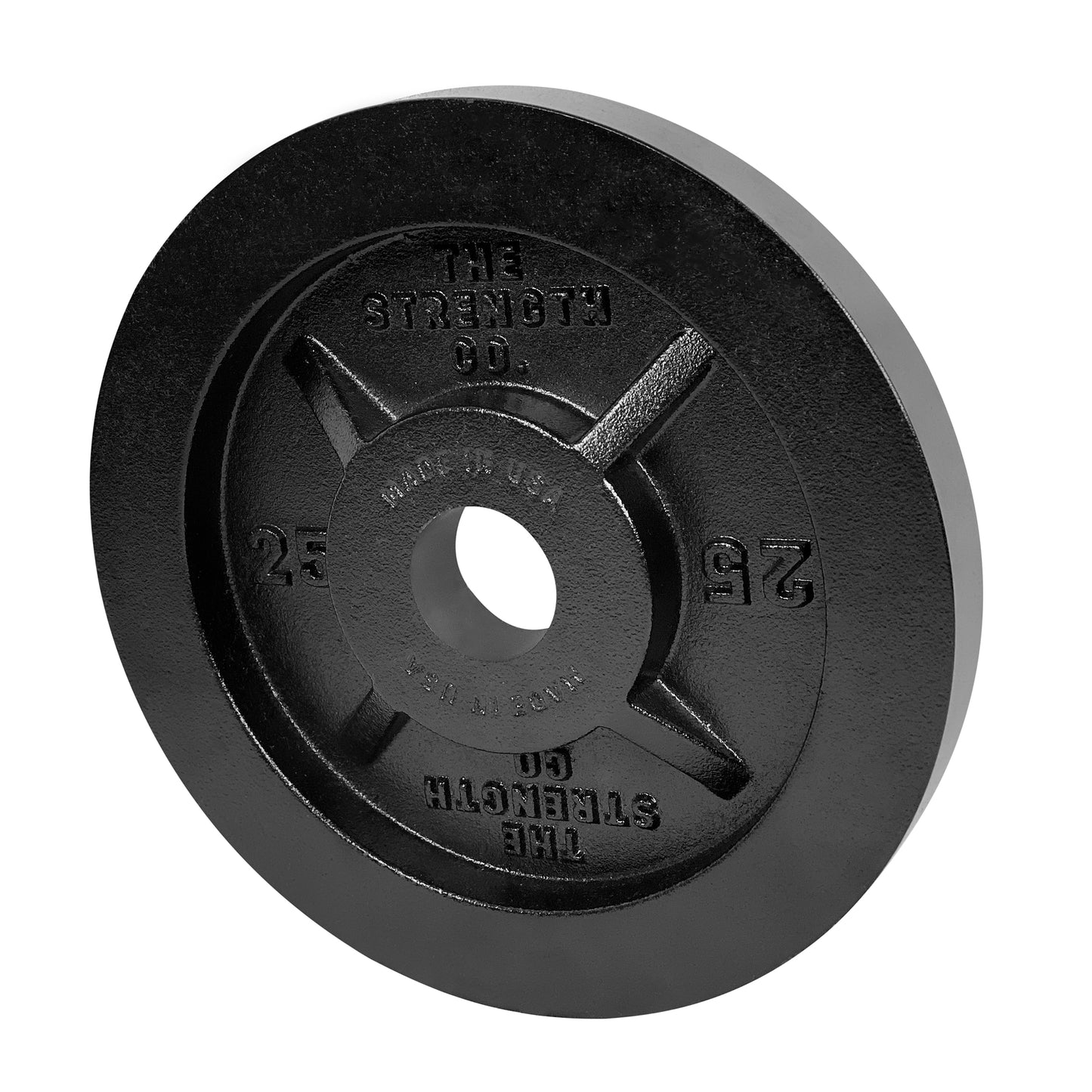

Our design process ensured function for the everyday lifter. The deep lip on the edge of the plates allow for great handling and our largest plate width of only 1.25” leave plenty of room on the bar for more weight. The inner diameter of 1.99” ensure a snug fit on the barbell sleeve – the tightest on the market.

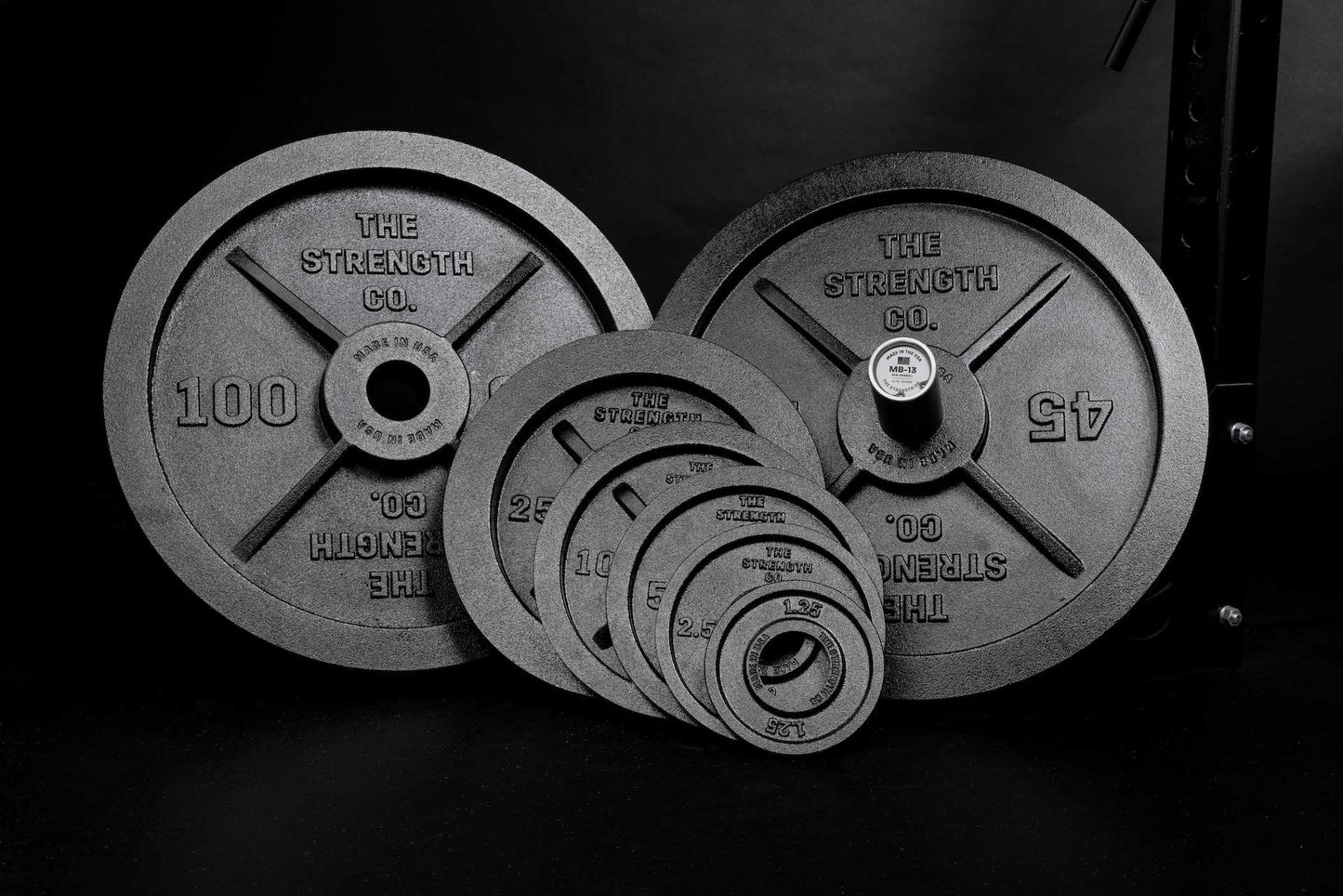

We also have gym sets of iron Olympic plates and barbells.

100LB – 17.75” (diameter) 2.25” (width) *2.01" inner diameter

45LB – 17.75” (diameter) 1.25” (width)

35LB – 14.75” (diameter) 1.25” (width)

25LB – 11.75” (diameter) 1.25” (width)

10LB – 9.13” (diameter) 0.88” (width)

5LB – 8” (diameter) 0.63” (width)

2.5LB – 6.5” (diameter) 0.5” (width)

1.25LB – 5” (diameter) 0.3” (width)